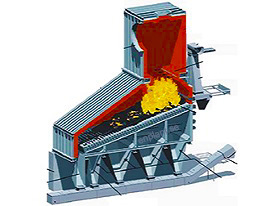

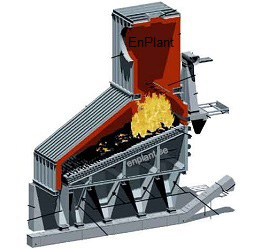

BIOMASS FIRED FURNACE

Hot gas generator (furnace) with reciprocating grate is the most effective design for complete combustion of waste wood fuels, with varying characteristics, fuel size, fuel heating values and high moisture content.

BIOMASS FUEL

The HGG (furnace) can be fired with a range of waste wood as, bark, saw dust, wood chips, trimmings and sander dust.

RECIPROCATING GRATE

Utilizing Biomass energy by waste wood with higher moisture content fuels such as hogged bark and green wood for larger firing capacities demands a reciprocating grate in order to get continuous operation, stable and easily adjustable combustion results. EnPlant, proprietary reciprocal grate design was delivered for the first time 1991.

COMBUSTION CHAMBER

The waste wood is burned in a combustion chamber. A true complete combustion requires good mix of the carbon monoxide and supply of the oxygen-rich air, high temperatures and retention time. With consider on this facts are our combustion chambers designed for each job in order to ensure ideal combustion. EnPlant, proprietary CPF technology ensure that the furnace energy capacity of your plant demands are consistently met.

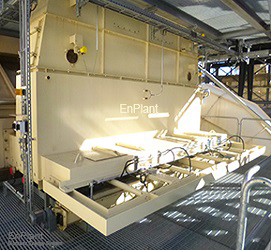

FUEL FEEDER

Fuel is feed into the fuel hopper via the fuel feed conveyor. The integrated fuel pushers are programmed to evenly distribute the fuel onto the furnace Grate front to maintain even fuel pile on the Grate.

FUEL HANDLING

Engineered and designed to work with your furnace and, to deliver the amount of fuel required. Fuel feed system designed for specific HGG ensuring that the energy needs of your plant are consistently met.

ASH HANDLING

The Submerged Ash Conveyor collects ash from under a wood fired or biomass fired energy system. The Conveyor is located right underneath the Reciprocating grate, Secondary chamber.

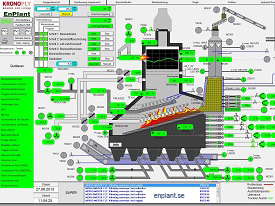

CONTROL SYSTEM

Control systems for biomass fired energy systems are complex due to the integration of fuel handling, combustion control, and ash removal.

What can you get from us

Whether you need individual replacement components or a whole new system designed from scratch we, are capable of supply a wide variety of equipment, system and packages.

We are capable provide.

With our own in-house design capabilities complete package system including: Consulting, Design, Engineering, Manufacturing, Installation, Supervision and Parts.

Top rate Quality

The design, engineering, and manufacturing of our systems are backed by decades of energy experience, or with other words with over 50 years experiences brings along we can guarantee quality in all the manner of our system and products, from routine to complex.

EnPlant PROJECTS

We are experienced industry veterans who will learn about your application to provide solutions specific to your plant needs. For industrial clients EnPlant provide Biomass-fired energy system, Fuel Hanlings sytems and related equipment.

EnPlant Reciprocating Grate Technology is used largely in the industry. EnPlant, proprietary reciprocal grate design was delivered for the first time 1991.

ENPLANT PRODUCTS

We provide complete package waste wood biomass energy systems for industry, with brand EnPlant.

Whether you need individual equipments, products, replacement components or a whole new system we are capable provide by our own design Fuel handling system, Push bottom Ladders, Drag Chain conveyors, Srew conveyors, Fuel feeder, Inermetiate bin, Reciprocal grate system, Wet ash conveyor, Ash handling systems, Dust burners, Dosing bins, Silos, Disc screen, HGG boiler, Grate bars.

If you also as many industry clients during decades has become interested of our systems or individual equipment and, want to know more and if you have any question please don't hesitate to contact us.

The below pictures show you EnPlant products, equipment and system. O.E.M and design by EnPlant.

Biomass Furnace

Combustion chamber

Fuel Handling

Fuel Handling System

Push Bottom Ladders

Live bottom bins

Reclaim bin

Fuel bin dicharge

Fuel Feeder

Furnace Feeder

Reciprocal Grate

Furnace Grate system

Furnace chamber

Hot Gas Generator

Wet ash conveyor

HGG Ash system

Intermediate bin

Surge Feeder bin

Dust Burner

Furnace Dust burner

Hot water boiler

HGG Hot water plant

Drag Chain Conveyor

Material Handling system

Screw Conveyor

Material handling system

Material bin

Material handling system

Dosing Bin

Material handling system

Disc Screen

Material-Fuel Handling

Why ENPLANT

EnPlant say, our commitment to provide solutions specific to your plant needs. Based by on our and your experiences we will works towards ensuring an specific solution for all clients.

Corporate Office:

EnPlant Engineering AB

Förrådsvägen 16

SE-14440, Rönninge

Sweden

info@enplant.se

+46853032878

Copyright © EnPlant Engineering AB All Rights Reserved 2023